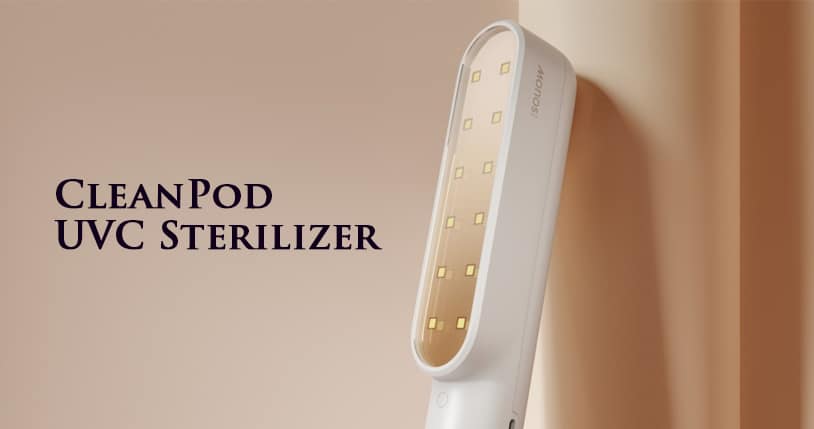

CleanPod UVC Sterilizer, Ultraviolet, Beams, object

Cleanpod UVC sterilizers are an essential tool to protect against the invisible bacteria that can be found in everything you touch at home or on the go. When the button is pressed, a dedicated LED emits a high-energy beam of UVC (ultraviolet C) light, effectively eradicating the surface without using chemicals. UVC light is 30 seconds and can kill up to 99.9% of disturbing bacteria. Unlike conventional UVC lamps, clean pod LEDs are mercury-free and immediately powered on without warm-up time. It is also precisely designed to output UVC light of high bactericidal wavelength. This reusable portable disinfectant is more environmentally friendly than a chlorox wipe.

History

The clean pod was designed to protect against the invisible bacteria Vibrio. It uses UVC (ultraviolet C) lights to sterilize up to 99.9% of bacteria that come in contact with it. The UVC light is illuminated by special LEDs that can sterilize surfaces without the use of chemicals. Clean pods are mercury-free and are designed to deliver UVC light at wavelengths that are highly bactericidal. It is very portable and can be stored in most small bags or wallets. It also comes with a safety lock switch to prevent accidental turning on of power when carrying. Clean pods are environmentally friendly alternatives to disposable wipers because they are cleaned with light, not chemicals. No warm-up time is required.

UV sterilization contributes to health promotion in many industries

UV sterilization systems have been proven to improve people’s health and well-being in many industries and environments. UVC sterilization protects people from harmful bacteria, viruses, molds, and other pathogens in many of these industries and applications.

Food industry

UV lamps are used for irradiation. UV sterilization can also kill viruses, bacteria, yeasts, and fungi in seconds, extending shelf life and nutritional value. In food applications, it is used to sterilize mold and bacteria in packaging materials, conveyor belts, transport containers, work surfaces, countertops, and liquid sugar tanks.

UV Hormesis

A promising new technology for the process of delaying fruit and vegetable ripening and reducing post-harvest losses. This technology has the potential to lead to significant cost savings in the future.

Household Air Purification

“Ultraviolet Air and Surface Treatment” of the ASHRAE Handbook, the design goal for in-duct UV sterilization is to distribute UV energy uniformly in all directions throughout the length of the duct or air handling unit (AHU). This allows the air passing through the radiation zone to be irradiated with an appropriate amount of UV light. In addition, increasing the internal reflectivity of the air handling unit with materials such as aluminum can improve the performance of the UVGI, as the UVC energy reflects back to the irradiation zone and the effective ultraviolet light increases.

The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) also says that by placing ultraviolet sterilizers close to the equipment, it is possible to keep the cooling coil surface and condensed water pan clean. The irradiance of the industrial system is preferably in the range of 1,000 to 10,000 μW/cm2 but may be lower or higher depending on the application. Industrial Air’s sterilization system needs to be designed with the worst case in mind.

Air Purification in Health Care

A study by Avinash Kulkarni, Ph.D., Aeropure UV Systems Pvt Ltd, India, investigates the Tier 1 and Tier 2 types of UV-ray air purification systems in health care facilities. The Tier 1 system is considered a UVGI on the AHU’s Cooling Coil, and the Tier 2 system is defined as a local Upper Room UVGI. Studies have repeatedly shown that the number of bacteria in both Tier1 and Tier2 systems decreases by 70% to 80%.

UV sterilization technology is a key part of air conditioning systems that are designed to kill pathogens that cause disease and pollutants that worsen respiratory diseases in hospitals and other environments.

Industrial Air Purification

UV lamps are used to remove hazardous and toxic chemicals from many industries, as well as to reduce and eliminate VOCs and industrial emissions that contain solvents.

UV surface disinfections

UV surface sterilization is used to kill bacteria and prevent the spread of bacteria and fungi. For example, in the packaging industry, UV sterilizers are used to provide effective and efficient sterilization of packaging materials. There are also examples in the food industry where UVCs are used to increase the shelf life of food products. These are just a few examples of the use of ultraviolet surface disinfection. The effect of UV light on surface sterilization varies depending on the type of material being sterilized. This is related to both the type of bacteria (e.g. Escherichia coli and its stains) and the texture of the surface. Sterilization is done only if the bacteria see the UVC. In other words, the texture of the exposed surface should not be too rough.

Objects of UV Sterilizers

UVC team

The UV team was developed to sterilize air and surfaces in production with UV-C. Suitable for packaging lines and sorting areas for food and pharmaceutical products. Modules can be of various lengths and can hold up to 10 UV lamps. Other options include UVLON shutter protection to protect lamps and frames.

The modules are easy to install and have built-in electronic ballast. Each module also has an external control box, equipped with various monitoring tools.

CV-CBELT

The UV technique CV-CBELT was designed for UV surface sterilization in production lines. The irradiated UV rays greatly reduce the risk of contamination of the surfaces and packages of conveyor production lines by microorganisms.

Features

1. UV-C Amalgam Lamp (253.7 nm)

2. Stainless steel body AISI 304.

3. Driven by an electronic ballast

4. Electrical control panel (IP66, S.S. AISI 304)

5. Main power supply 230 V, 50/60 Hz

6. CE mark (LVD -EMC -MD -RoHS)

Pron

1. Control of early food spoilage (extension of best before date)

2. To reduce the risk of consumer infection due to contact with contaminated packaging material.

3. Chemical disinfection of packaging materials and conveyor belts is not required.

UV discoron

The UV discoron is designed for the disinfection of public transportation such as buses, trains, buses, and airplanes. This includes all surfaces that can be found in public transport, such as all seats, handles, buttons, and rails. This device is a ramp-type ozone generator that, unlike discharge-type devices, does not produce harmful nitrogen oxides.

How do you use it?

This mobile device can be left on a bus, for example. Doors, windows, and vents should all be closed and no one should be present while driving. This machine can sterilize an area of up to 50 cubic meters. For larger areas, additional equipment may be used. The unit operates for one hour and can remove 99.99% of viruses. During the first 3 hours of operation, do not touch the unit and do not allow people to enter the disinfection area. This allows time for the natural degradation of harmful ozone.

Generates ozone.

UVC Star

The UVC Star is a ceiling-mounted model developed by UV Technik. Indoor sterilization includes microbiological sterilization of air and surface. This reduces the need for chemical disinfection and may even eradicate it. The three UV lamps are illuminated at 360 degrees. The powerful lamp takes only 10 minutes to work. For safety when using the UVC Star, the remote control is included, as well as an automatic microwave-assisted shutdown and three infrared motion sensors.

UV tunnel

The UV tunnel was developed by UV Technik as a conveyor irradiator. This can be used in applications such as airport security check zones, for example. UVC chambers significantly reduce the microbiological and virological contamination of surfaces and packages on conveyors and production lines. This safe, light-shielded UVC chamber undergoes a chemical-free sterilization process.

Summary

Now you can’t be off guard – even if it’s standard bacteria. Thanks to CleanPod, we can fight germs and feel a little more at ease when we are trying to complete simple tasks such as decontaminating daily mail and doorbells. However, I think that there is a simple way to determine whether it is functioning or not other than taking samples and analyzing them in the laboratory. Aside from that, I think CleanPod is the best option for disinfecting objects.

Read more: